YG11C YG15 YG15C Cementati per lamelle di carburo di tungsteno per rulli di rottura ad alta pressione

Dettagli:

| Luogo di origine: | Hunan, Cina |

| Marca: | Rixin |

| Numero di modello: | 20×45 |

Termini di pagamento e spedizione:

| Quantità di ordine minimo: | 1 |

|---|---|

| Prezzo: | $49 |

|

Informazioni dettagliate |

|||

| Materiale: | Carburo di tungsteno | Trattamento superficiale: | Finisci a terra |

|---|---|---|---|

| Grado: | YG11C, YG15, YG15C, YG18, YG20 | Trs: | > 3000 N/mm3 |

| Durezza: | 85-92 HRA | Durata di servizio: | 10.000 - 30.000 ore |

| Fonte di energia: | Elettrico | Tipo di motore: | Elettrico |

| Superficie: | Rivestito | Misurare: | Personalizzato |

| Utilizzo: | Rullo di macinazione ad alta pressione, minerale di ferro, frantumazione del cemento | Prestazione: | Elevata durezza, robustezza, resistenza agli urti |

| Densità: | Alto | Resistenza all'usura: | Alto |

| Resistenza agli urti: | Alto | ||

| Evidenziare: | YG11C Sottili di carburo di tungsteno,YG15 HPGR Studs,YG15C per strisce di carburo |

||

Descrizione di prodotto

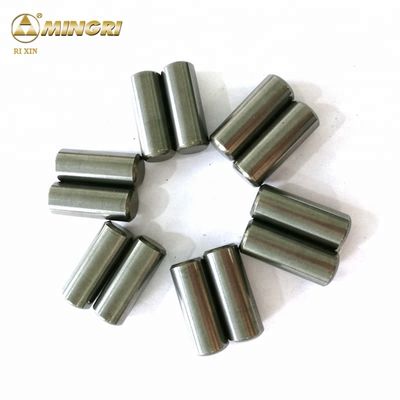

OEM personalizzabile testa di sfera di ferro rulli presse di rettifica HPGR Stanghe Pini Carburo di tungsteno cementato parti utensili

Visualizzazione del prodotto

| Articolo | di peso superiore a 20 g/m2 |

|---|---|

| Grado | L'accesso all'aeroporto è soggetto a un'autorizzazione di cui all'articolo 6 del regolamento (CE) n. 1370/2008. |

| Dimensioni | Standard o personalizzato |

| Marchio | Rixin |

| Paese di origine | Zhuzhou, Cina |

| Utilizzatori | Rulli di rottura ad alta pressione, minerale di ferro, triturazione del cemento |

Con eccellenti proprietà di alta durezza, resistenza e resistenza agli urti.tali puntini migliorano significativamente la durata di vita e l'efficienza di lavoro delle macchine HPGRRispetto ai tradizionali rulli a faccia dura, i perni di carburo di tungsteno offrono una durata di vita fino a 10 volte superiore.

Specifiche tecniche

Dimensioni e tipi disponibili

Imballaggio e consegna

Capacità di produzione

Siamo specializzati in tutti i tipi di profili e matrici di carburo di tungsteno, strumenti di taglio, strumenti minerari, parti di usura e parti di utensili non standard personalizzate con alte prestazioni nel settore.

Assicurazione della qualità

Il nostro processo di produzione comprende la miscelazione della polvere, la spremitura, la sinterizzazione, la finitura e il trattamento superficiale..

Tutti i prodotti sono sottoposti a una rigorosa ispezione ad ultrasuoni prima della spedizione per garantire l'assenza di difetti come i pori.

Profilo aziendale

Informazioni di contatto

Vuoi conoscere maggiori dettagli su questo prodotto