Blocco bordo in carburo di tungsteno personalizzabile di grado YG11C YG15 YG15C per rulli di macinazione ad alta pressione

Dettagli:

| Luogo di origine: | Hunan, Cina |

| Marca: | Rixin |

| Numero di modello: | Perno in carburo di tungsteno-3 |

Termini di pagamento e spedizione:

| Quantità di ordine minimo: | 1 |

|---|---|

| Prezzo: | $59 |

|

Informazioni dettagliate |

|||

| Materiale: | Carburo di tungsteno | Trattamento superficiale: | Finisci a terra |

|---|---|---|---|

| Superficie: | Lucido | Grado: | YG11C, YG15, YG15C, YG18, YG20 |

| Trs: | > 3000 N/mm3 | Durezza: | 85-92 HRA |

| Durata di servizio: | 10.000 - 30.000 ore | Fonte di energia: | Elettrico |

| Tipo di motore: | Elettrico | Utilizzo: | Rullo di macinazione ad alta pressione, minerale di ferro, frantumazione del cemento |

| Misurare: | Personalizzato | Resistenza agli urti: | Alto |

| Resistenza all'usura: | Alto | Densità: | Alto |

| Prestazione: | Lunga vita | ||

| Evidenziare: | Blocco bordo in carburo di tungsteno di grado YG11C,Blocco bordo HPGR di grado YG15,Blocco bordo in carburo cementato di grado YG15C |

||

Descrizione di prodotto

Parti di usura personalizzabili per rulli di macinazione ad alta pressione

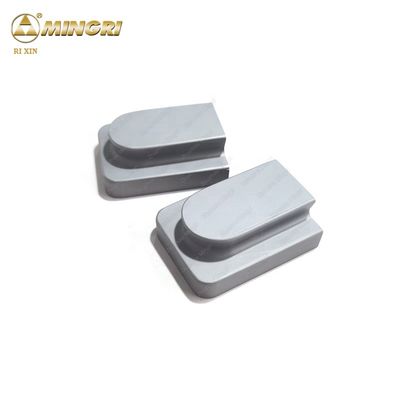

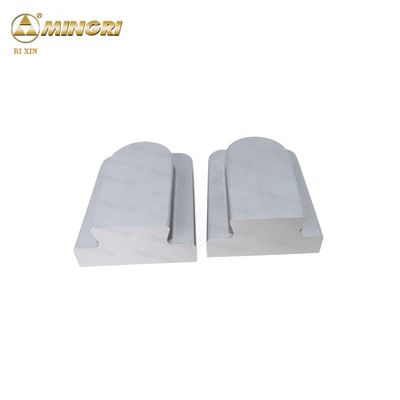

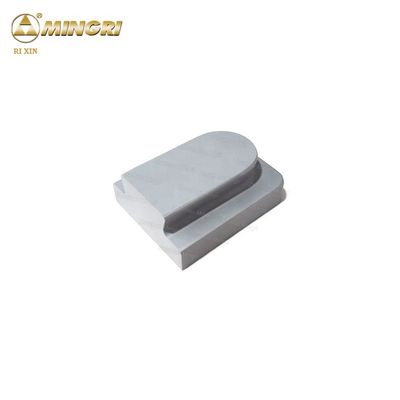

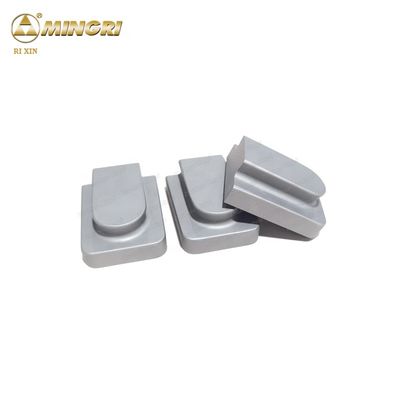

Blocco bordo in carburo di tungsteno per macchine HPGR

| Articolo | Blocco bordo in carburo di tungsteno |

|---|---|

| Grado | YG11C, YG15, YG15C, YG18, YG20 |

| Dimensioni | Standard o personalizzate |

| Marchio | Rixin |

| Paese di origine | Zhuzhou, Cina |

| Utilizzo | Rullo di macinazione ad alta pressione, minerale di ferro, frantumazione del cemento |

I blocchi bordo in carburo di tungsteno sono componenti essenziali per le macchine HPGR (High Pressure Grinding Roller). Con proprietà eccezionali tra cui elevata durezza, resistenza e resistenza agli urti, queste parti migliorano significativamente la durata di servizio e l'efficienza operativa della macchina. Rispetto ai rulli di riporto tradizionali, i blocchi bordo in carburo di tungsteno offrono fino a 10 volte la durata di servizio.

Specifiche del prodotto

Capacità di produzione

Siamo specializzati nella produzione di vari profili in carburo di tungsteno, tra cui utensili da taglio, utensili per l'estrazione mineraria, parti soggette a usura e parti di utensili personalizzate con prestazioni superiori per applicazioni industriali.

Processo di produzione

Il nostro processo di produzione completo include miscelazione delle polveri, pressatura, sinterizzazione, finitura e trattamento superficiale. Con centinaia di attrezzature aggiornate, manteniamo una capacità di produzione mensile di 50 tonnellate, garantendo al contempo eccellenti standard di qualità.

Controllo di qualità

Tutti i prodotti sono sottoposti a rigorosi controlli a ultrasuoni per eliminare eventuali difetti prima della spedizione. I nostri materiali ad alta densità con elevata resistenza all'usura e agli urti garantiscono una maggiore durata del prodotto.

Profilo aziendale

Vuoi conoscere maggiori dettagli su questo prodotto